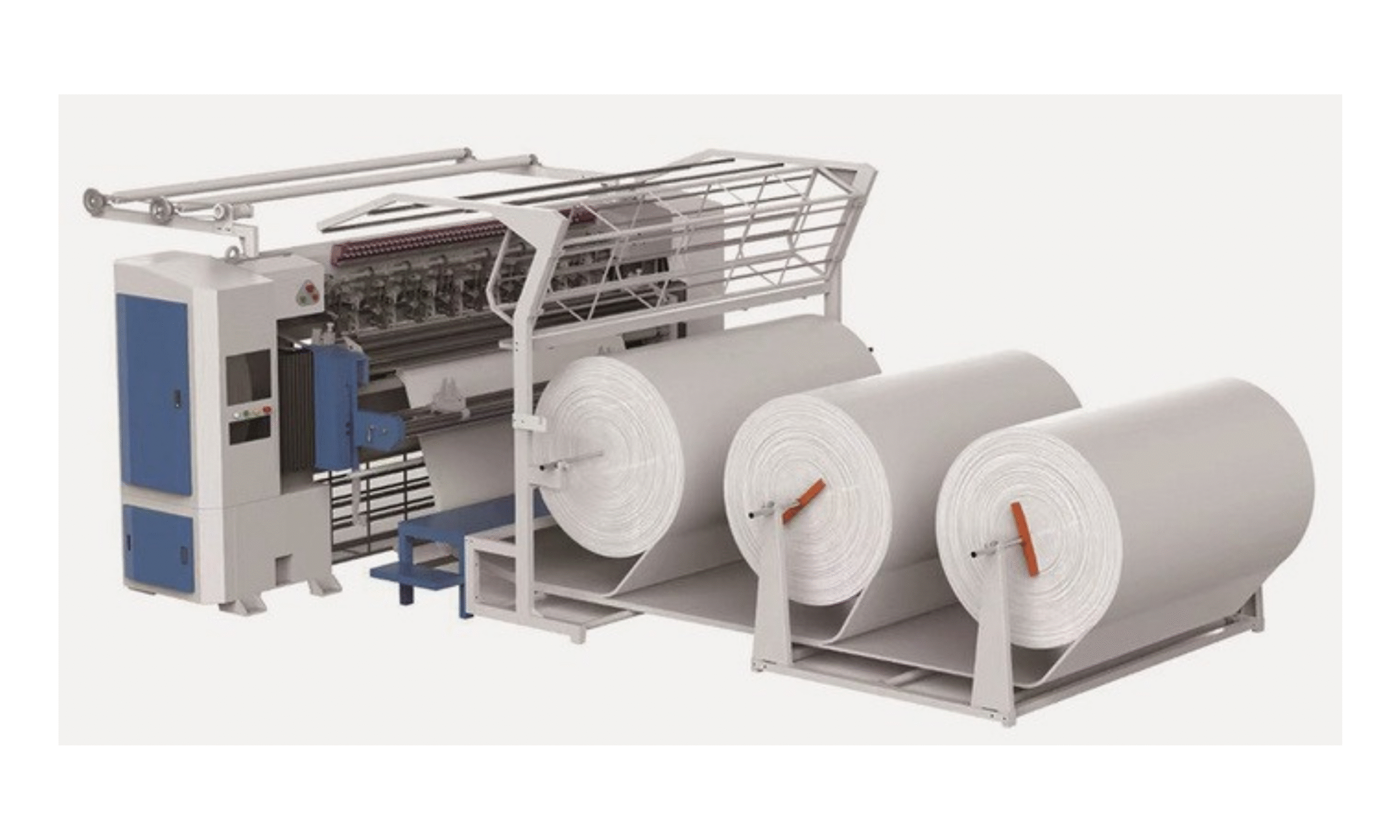

| Parameter | Value |

|---|

| Dimension | 7400 x 4990 x 2520 mm |

| Power | 380 V, 50 Hz, 11 kW |

| Speed | 900 – 1200 rpm |

| Gross Weight | 5800 Kg |

- FEATURES

•Row pitch: 0.5 inches, can be processed

more specification

patterns.

• Slitting device with saddle pendulum more

accurate kinetic

energy cutting good around.

• Automatically set needle on Third row needle bar not affected by the position of the pallet.

• Update needle bar working way, Needle row drive swing arm made by special aluminumalloy, make machine perform swing lighter and faster.

• Hatchell drive swing arm with special aluminum after finishing the surface treatment, more stable in operation, to achieve lower vibration effect.

• Advanced computer control system and mechanical manufacturing process, so that the higher mechanical performance, speed, output increased.

• Hatchell and plate adopts double rocker mechanism without cam, without refueling oil to avoid the phenomenon of fabric.

• Advanced and practical automatic detection,bottom and surface thread broken,machine stop automatic, hand close to the infrared sensor can automatically stop too.

• The spindle is controlled by 6KW servo motor. Precise PID algorithm control, automatic needle saddle and roller adopts servo drive equipment, can be 360 degree free quilting and multiple step quilting.

• A new generation of computer quilting control system, high precision, no need modification pattern, computer numerical control speed, maximum speed up to 1500 gauge needle/min, 3- 8mm arbitrarily set. • Pattern using CAD drawing, easy to learn, accurate drawing and automatically reset to zero.

• Can set the length of quilting operation after the completion of the automatic stop.

• And automatic zero tracking operation pattern. The running state of track, automatic detection, machine operation at a glance